Your Partner in Innovative Manufacturing

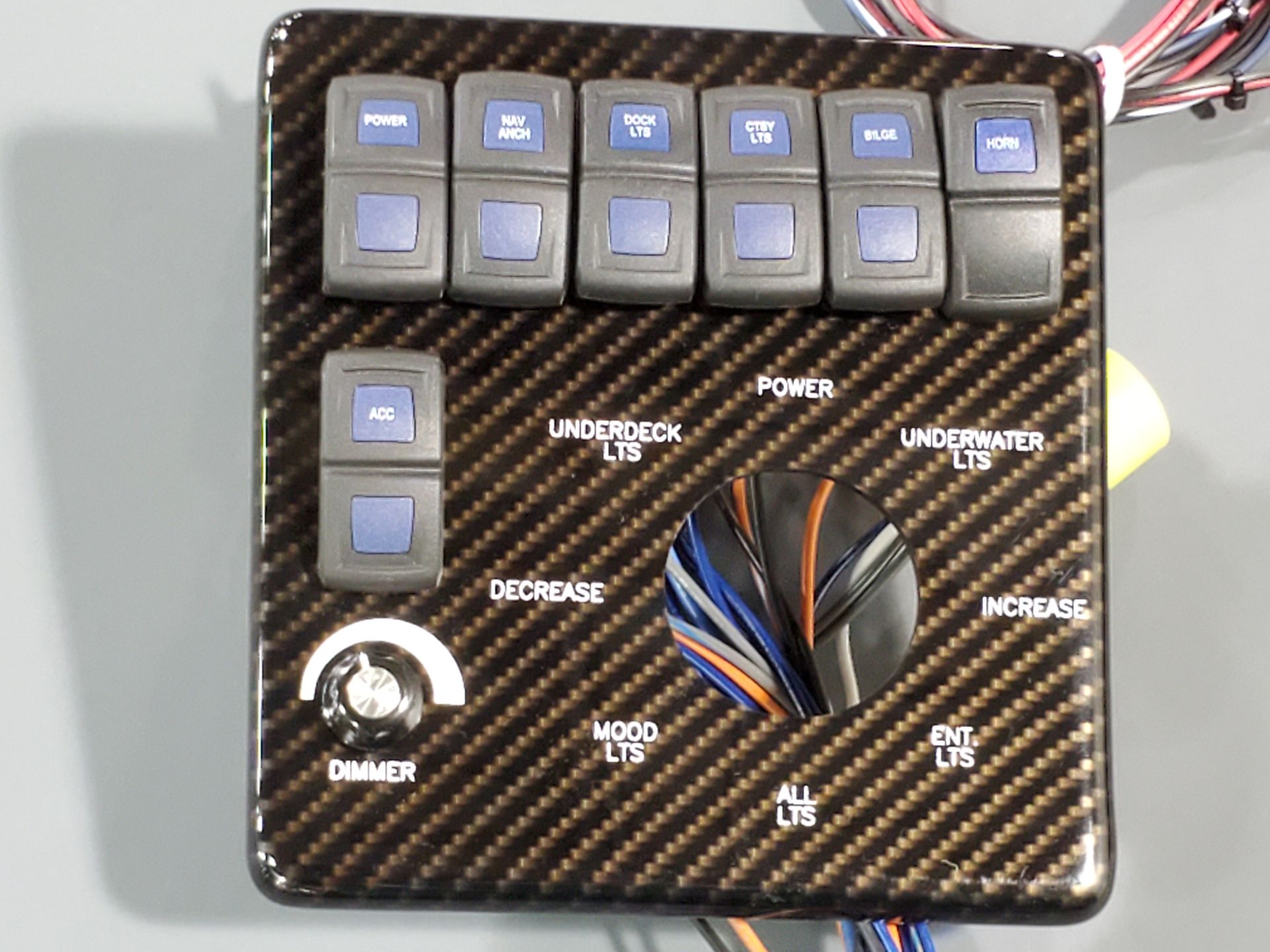

For over 30 years, Uniforce has delivered advanced plastics, tooling, thermoforming, 3D printing, wire harnessing, and electrical assembly services. As a full-scale, integrated manufacturer, we design, engineer, and build high-quality products with precision, efficiency, and competitive pricing.

30+

Years of Experience

About Us

Innovation, Precision, Partnership

Founded in 1990 as an electronics developer, Uniforce has grown into a comprehensive manufacturing partner trusted by OEMs across multiple industries. With more than three decades of experience, we provide engineered solutions backed by advanced equipment, expert craftsmanship, and seamless prototype-to-production support.

Sustainable Manufacturing

Advanced Automation

Efficient Production Processes

Reliable Delivery Services

Services

OUR CAPABILITIES

Uniforce combines advanced technologies with proven manufacturing methods to deliver fully customized solutions. Explore our core areas of expertise:

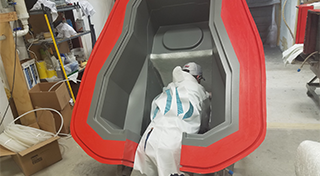

Plastics & Tooling

- Handmade, two-part fiberglass tooling

- Enables deep draws & intricate shapes

- Automated 5-axis CNC machining & robotic cutting

- Marine-grade, hand-wrapped vinyl finishing options

- Fast production timelines (3–5 days for tooling)

3D Printing

- Ideal for prototyping and design validation

- One-step process with 48-hour turnaround

- Large-format prints up to 10 ft.

- Cost-effective and efficient for rapid iteration)

Uniforce Composites

Read More ⇢

Uniforce Plastic

Read More ⇢

Uniforce Tech

Read More ⇢

Industries We Serve

Uniforce supports OEMs and manufacturers across a variety of advanced industries. While marine remains our largest market, our capabilities scale seamlessly across multiple sectors:

- Marine – Dashboards, shifters, cup holders, speaker panels, iceboxes & more.

- ATV/UTV – Durable plastics, electrical harnesses, dashboard assemblies.

- Heavy Highway Vehicles & School Buses –lectrical assemblies, large tooling, custom panels.

- Agriculture – Rugged plastics and electrical components for demanding environments.

10k+

Completed Project

15+

Satisfied Customer

500k+

Parts Delivered

What We Do

THE UNIFORCE ADVANTAGE

At Uniforce, we deliver more than parts — we provide complete solutions.

Our process is built on speed, customization, and seamless OEM support.

Fast Turnaround

Prototyping & tooling in as little as 48 hours with in-house 3D printing.

Integrated Services

Plastics, tooling, thermoforming, harnessing & assembly under one roof.

Cutting-Edge Technology

5-axis CNC machining, robotic cutting cells & Delta Sigma projection systems.

OEM Ready

Direct-to-line shipments & customer-specific designs for seamless integration.

Let’s make something great work together.

Delivering Excellence Through Every Project

Every project we take on benefits from meticulous engineering, quality control, and attention to detail. Whether it’s custom plastics, advanced electrical assemblies, or precision tooling, we are committed to creating long-lasting value for our clients.

Integrated Manufacturing for Maximum Precision

Our process is built to optimize accuracy, efficiency, and quality at every stage. With advanced technologies and coordinated workflows, Uniforce delivers consistent, dependable results for OEM partners.

01

Understanding Your Needs

We collaborate to define specifications, performance goals & timelines.

02

Engineering & Prototyping

Rapid prototyping, tooling, and large-format 3D printing.

03

Production & Assembly

Automated thermoforming, CNC trimming, electrical assembly & testing.

04

Quality Control & Delivery

Every component is measured, tested, and prepared for seamless integration.